3D Printing Services

Polyjet Colour 3D Printing

We use the Stratasys J850 for transparent, bendable, colourful prints.

Feature name

Share useful information about your product features.

Resin 3D Printing

The best option for surface details.

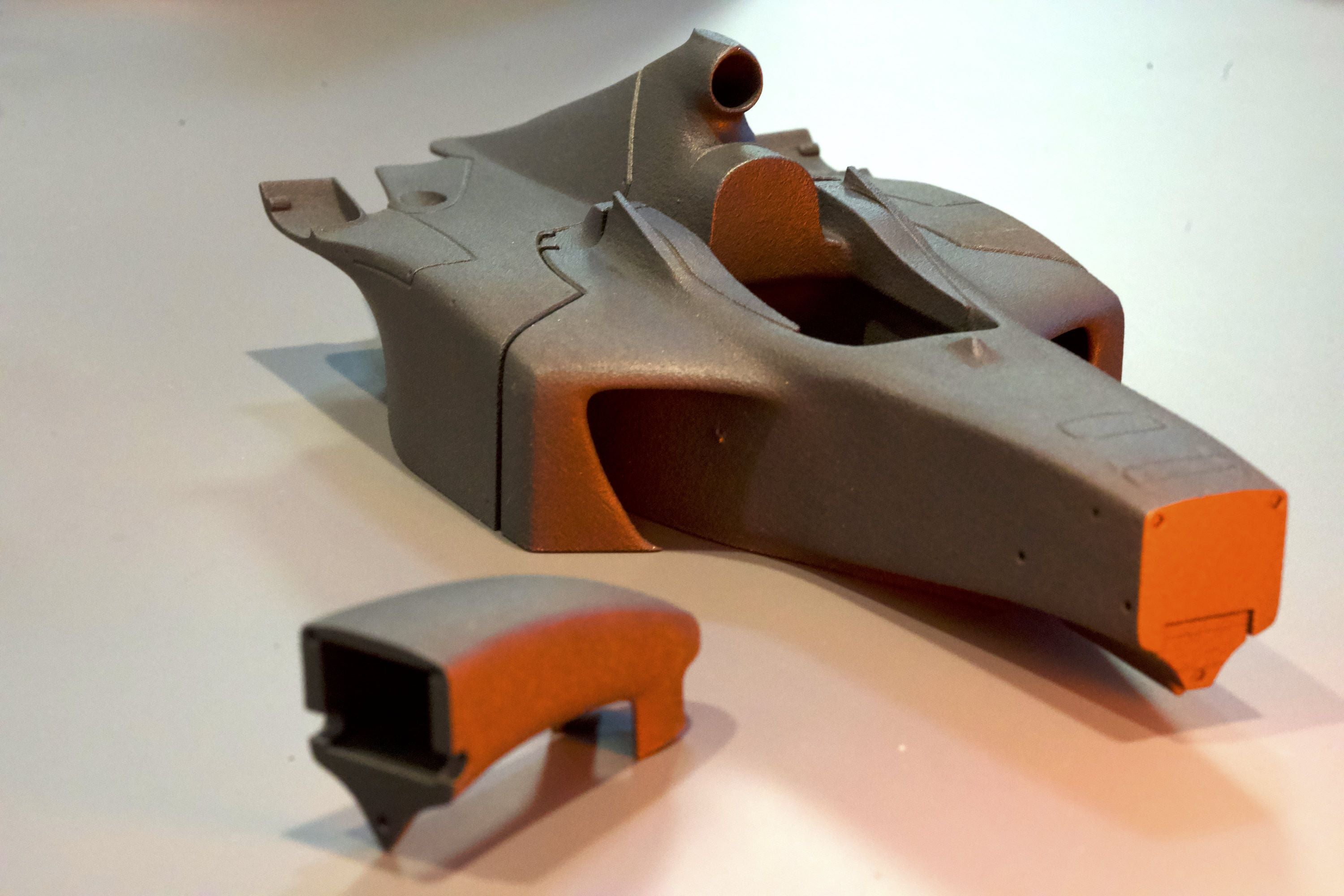

FDM 3D Printing

The most economic option, durable but not as detailed as resin printing.

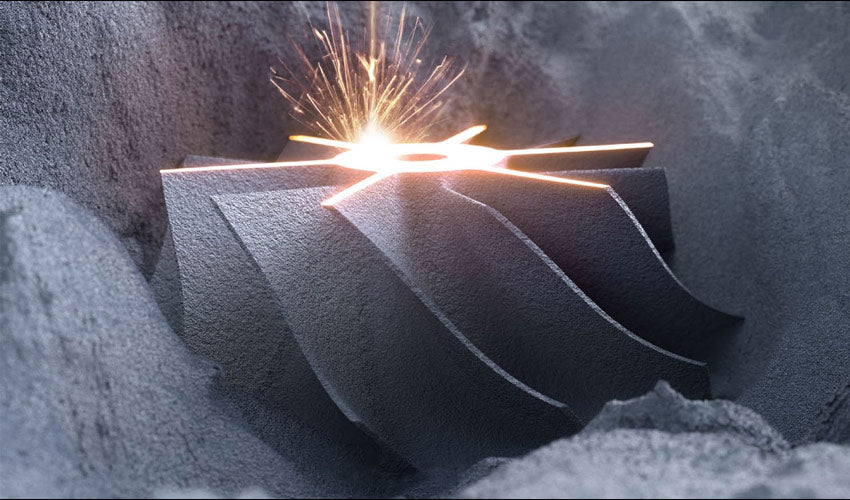

Metal 3D Printing

Our printer utilises aluminium-magnesium alloy powder.

3D Printing Services

We are dedicated to creating complex and accurate innovative designs. We offer budget-friendly prototyping solutions, satisfying different needs for people from the creative-maker level to the professional industrial level.

For polymer 3D printing, we provide a wide range of material selection. We support various advanced engineering-grade materials such as PC, PEEK and PEI. Advanced plastic materials nowadays possess great heat and tension tolerance properties, and can be used in industrial, mechanical and even medical applications.

For metal 3D printing, our SLA printer utilises aluminium-magnesium alloy powder to produce small batches of robust metal parts with excellent mechanical properties, at an unprecedented level of cost-effectiveness compared to conventional molding technology.

Stratasys Polyjet

We offers 3D colour printing services using PolyJet technology and a full-colour multi-material 3D printer that mixes 7 materials simultaneously to achieve 500,000 colours, different textures, transparency and softness to produce smooth, accurate parts, prototypes and tools.

PolyJet is a powerful 3D printing technology that produces smooth, accurate parts, prototypes and tooling. With microscopic layer resolution and accuracy down to 0.014 mm, it can produce thin walls and complex geometries using the widest range of materials available with any technology.

Materials Selection

● ABS (acrylonitrile butadiene styrene)

● Composites (carbon fiber, kevlar, fiberglass)

● HIPS (high impact polystyrene)

● Metal (aluminium magnesium alloy)

● Nylon

● PETG (polyethylene terephthalate glycol)

● PLA (polylactic acid)

● PVA (polyvinyl alcohol)

● TPU (thermoplastic polyurethane)

● Resin with different properties

● Polyjet resin with different properties

Order Process

1. Provide STL File & Printing Requirement

Send us your STL file and let us know your printing requirement via WhatsApp (9809 3648), or Email them to info@dot3dfactory.com

*If you do not have a STL file, you can consider our 3D Modeling Service or 3D Scanning Service. For more details, please refer to the 3D Modeling Service Order Process or the 3D Scanning Order Process.

2. Select Printing Technology & Material

After understanding the purpose and placement environment of the printed items, we will provide you with professional advice for reference. We will suggest the most suitable printing technologies and material for you to consider.

3. Get Quote & Estimated Print Time

Once the file is revised and checked, we will provide you with a quote. Project lead time is about 2-10 working days in general.

Price varies depending on multiple factors, including the complexity of the file, printing technology, estimated printing time, materials, printing quality and post-production requirements.

4. Carry Out the Printing Process & Arrange for Product Inspection and Delivery

After receiving the deposit, we will proceed with the project. You are welcome to check the printing result. You can choose to pick up your print at our store or choose a suitable delivery service.

3D Printing Services

We are dedicated to creating complex and accurate innovative designs. We offer budget-friendly prototyping solutions, satisfying different needs for people from the creative-maker level to the professional industrial level.

For polymer 3D printing, we provide a wide range of material selection. We support various advanced engineering-grade materials such as PC, PEEK and PEI. Advanced plastic materials nowadays possess great heat and tension tolerance properties, and can be used in industrial, mechanical and even medical applications.

For metal 3D printing, our SLA printer utilises aluminium-magnesium alloy powder to produce small batches of robust metal parts with excellent mechanical properties, at an unprecedented level of cost-effectiveness compared to conventional molding technology.

Stratasys Polyjet

We offers 3D colour printing services using PolyJet technology and a full-colour multi-material 3D printer that mixes 7 materials simultaneously to achieve 500,000 colours, different textures, transparency and softness to produce smooth, accurate parts, prototypes and tools.

PolyJet is a powerful 3D printing technology that produces smooth, accurate parts, prototypes and tooling. With microscopic layer resolution and accuracy down to 0.014 mm, it can produce thin walls and complex geometries using the widest range of materials available with any technology.

Materials Selection

● ABS (acrylonitrile butadiene styrene)

● Composites (carbon fiber, kevlar, fiberglass)

● HIPS (high impact polystyrene)

● Metal (aluminium magnesium alloy)

● Nylon

● PETG (polyethylene terephthalate glycol)

● PLA (polylactic acid)

● PVA (polyvinyl alcohol)

● TPU (thermoplastic polyurethane)

● Resin with different properties

● Polyjet resin with different properties

Order Process

1. Provide STL File & Printing Requirement

Send us your STL file and let us know your printing requirement via WhatsApp (9809 3648), or Email them to info@dot3dfactory.com

*If you do not have a STL file, you can consider our 3D Modeling Service or 3D Scanning Service. For more details, please refer to the 3D Modeling Service Order Process or the 3D Scanning Order Process.

2. Select Printing Technology & Material

After understanding the purpose and placement environment of the printed items, we will provide you with professional advice for reference. We will suggest the most suitable printing technologies and material for you to consider.

3. Get Quote & Estimated Print Time

Once the file is revised and checked, we will provide you with a quote. Project lead time is about 2-10 working days in general.

Price varies depending on multiple factors, including the complexity of the file, printing technology, estimated printing time, materials, printing quality and post-production requirements.

4. Carry Out the Printing Process & Arrange for Product Inspection and Delivery

After receiving the deposit, we will proceed with the project. You are welcome to check the printing result. You can choose to pick up your print at our store or choose a suitable delivery service.

Formlabs Fuse 1+

Strong End-use Nylon Parts

We use a laser powder printer for intricate and strong prints.

Stratasys J850 Prime

Full Colour 3D Printing

The creation of complex geometries, intricate details, full-color combinations, transparencies, and flexible parts - all in a single model.

Learn More

LCD Resin Printers

12K Resolution

We use LCD 3D printers for consistent, highly detailed resin prints.

Aluminium Magnesium Alloy

Metal SLM 3D Printing

We have a metal powder printing facility for printing durable metal parts.

Fused Deposition Modeling

The Basic Option

Old school and reliable.

Request a Quote

What do you want printed?

You can also send us 3D object files at our email: info@dot3dfactory.com