In the realm of modern manufacturing, few technologies have captivated imaginations and revolutionized industries quite like 3D printing. Often hailed as the harbinger of a new industrial era, 3D printing, also known as additive manufacturing, has fundamentally altered the landscape of design, prototyping, and production. But what exactly lies beneath the surface of this transformative technology? Let's delve into the principles and concepts that underpin the magic of 3D printing.

Understanding Additive Manufacturing

At its core, 3D printing is a process of creating three-dimensional objects layer by layer from digital models. Unlike traditional subtractive manufacturing methods that involve cutting away material from a solid block, additive manufacturing adds material incrementally, allowing for intricate designs and geometries previously unattainable.

The Three Pillars of 3D Printing

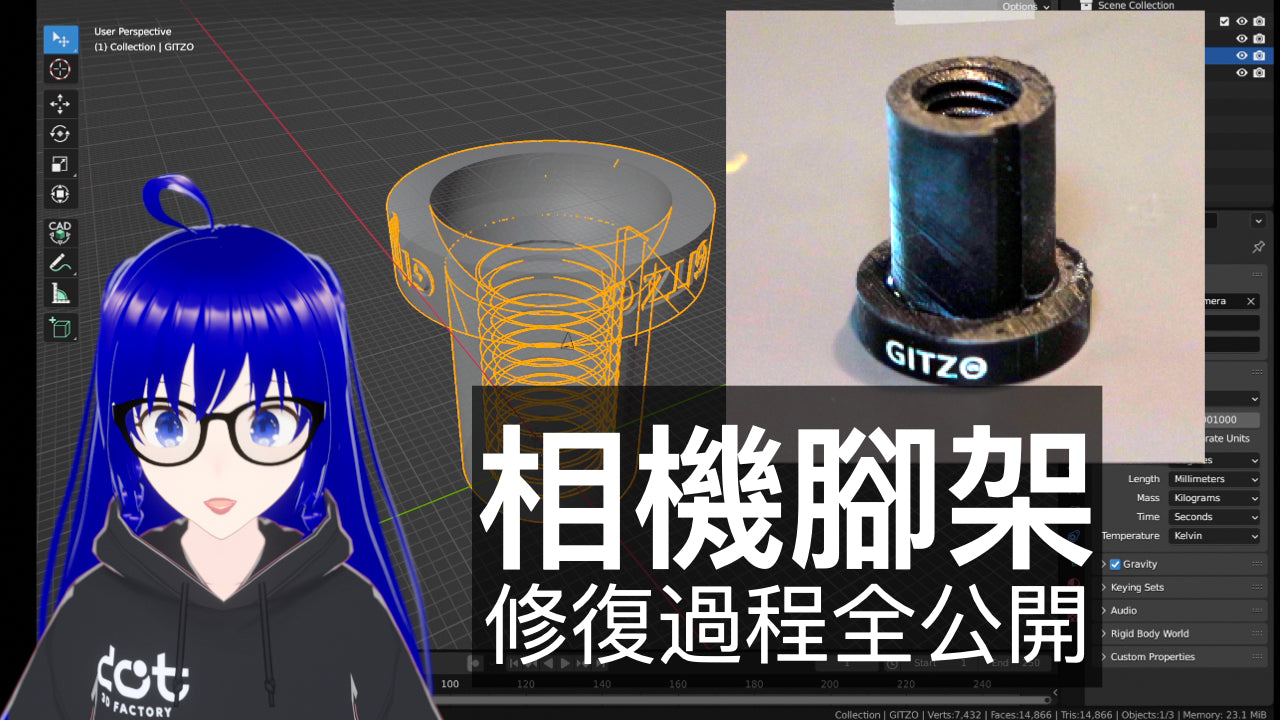

1. Digital Design

Central to the 3D printing process is the digital design phase. Utilizing computer-aided design (CAD) software, designers create virtual models of the desired object. These models are sliced into thin horizontal layers, generating a blueprint that guides the printing process.

2. Material Selection

The choice of material is crucial in 3D printing, as it directly impacts the properties and characteristics of the final object. From thermoplastics and metals to ceramics and even biomaterials, the range of materials available for 3D printing continues to expand, catering to diverse applications across industries.

3. Layer-by-Layer Printing

Once the digital model and material are selected, the 3D printing process begins. The printer interprets the sliced design and deposits successive layers of material according to the blueprint. Each layer fuses seamlessly with the previous one, gradually building up the object from the bottom up.

Types of 3D Printing Technologies

1. Fused Deposition Modeling (FDM)

FDM, the most common 3D printing technology, involves extruding thermoplastic filaments through a heated nozzle. The nozzle moves along predefined paths, depositing material layer by layer to form the object.

2. Stereolithography (SLA)

SLA utilizes a vat of liquid photopolymer resin and a UV laser to solidify the resin layer by layer. This technology excels in producing high-resolution, detailed parts with smooth surface finishes.

3. Digital Light Processing (DLP)

DLP technology employs a digital light projector to cure photopolymer resin layer by layer. It offers fast printing speeds and high resolution, making it suitable for applications requiring intricate details.

4. Liquid Crystal Display (LCD)

Similar to DLP, LCD 3D printing uses a liquid photopolymer resin cured by UV light. However, instead of a digital light projector, it utilizes an LCD panel to selectively mask light, curing the resin layer by layer. This technology provides excellent resolution and speed, making it ideal for producing precise, detailed parts.

5. Selective Laser Sintering (SLS)

In SLS, a high-powered laser selectively fuses powdered material, such as nylon or metal, into a solid structure layer by layer. This process enables the creation of robust, functional prototypes and end-use parts.

6. Selective Laser Melting (SLM)

SLM utilizes a high-powered laser to selectively melt and fuse metallic powders, layer by layer, to produce fully dense metal parts. This technology is widely used in aerospace, automotive, and medical industries for manufacturing complex, high-performance components.

Applications and Impact

The versatility of 3D printing transcends boundaries, finding applications across a myriad of industries. From aerospace and automotive to healthcare and fashion, 3D printing is reshaping traditional workflows, driving innovation, and unlocking new possibilities.

In healthcare, 3D printing facilitates the customization of medical implants, prosthetics, and surgical tools tailored to individual patient anatomy. In architecture and construction, it enables the rapid prototyping of architectural models and the fabrication of complex building components with intricate geometries.

Conclusion

As we unravel the principles and concepts of 3D printing, it becomes evident that this technology is more than just a manufacturing tool—it's a catalyst for creativity, efficiency, and progress. With its ability to transform digital designs into tangible objects with unprecedented precision and speed, 3D printing continues to push the boundaries of what's possible, ushering in a future where innovation knows no limits.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.